What certification systems are there for cosmetics manufacturing? Learn about ISO 22716 and Taiwan's voluntary cosmetics GMP in seconds

When many brand founders are searching for contract manufacturers, the most common questions are: “Do you have GMP?” or “What is ISO 22716? What’s the difference, and does it really matter?”

The answer is: It matters a lot! These certifications are not only guarantees of product quality, but also your ticket to entering international markets.

With the amendments to the Cosmetic Hygiene and Safety Act, certifications are no longer just a “bonus”—they are becoming a future “must-have.” This article will help you quickly understand the differences between these two certifications and how they benefit brand owners.

1. What Is ISO 22716? What Is Taiwan Cosmetic GMP?

Simply put, both are guidelines designed to ensure hygiene, safety, and consistent quality in cosmetic manufacturing:

1. ISO 22716:

Developed by the International Organization for Standardization (ISO), ISO 22716 is the international Good Manufacturing Practice (GMP) standard for cosmetics. It provides comprehensive guidance on personnel training, environmental control, equipment management, raw material and product traceability, and documentation. It is the globally recognized manufacturing standard for the cosmetics industry and is commonly required for export to the EU, United States, Southeast Asia, Japan, and Korea.

Achieving ISO 22716 certification indicates that a factory’s production processes, hygiene management, and quality control meet international standards, helping brands increase overseas cooperation opportunities and cross-border e-commerce success.

2. Taiwan Cosmetic GMP:

Established under Taiwan’s Cosmetic Hygiene and Safety Act, this is the national Good Manufacturing Practice standard for cosmetics. It is audited on-site by the Ministry of Health and Welfare (TFDA) or authorized institutions, requiring full compliance in facilities, environment, personnel, quality control, and record management.

2. ISO 22716 vs. Taiwan GMP at a Glance

| Comparison Item | ISO 22716 (International Certification) | Taiwan Cosmetic GMP (Mandatory Regulation) |

|---|---|---|

| Basis | Established by the International Organization for Standardization (ISO) | Established under the Cosmetic Hygiene and Safety Act |

| Applicable Markets | Main basis for global exports (commonly required in the EU, Southeast Asia, U.S., Japan, and Korea) |

Mandatory for domestic production in Taiwan starting 2026 |

| Role | International manufacturing standard for exports | Legal qualification for manufacturing in Taiwan |

| Auditing Authority | Third-party certification bodies (e.g., SGS) | Taiwan Food and Drug Administration (TFDA) |

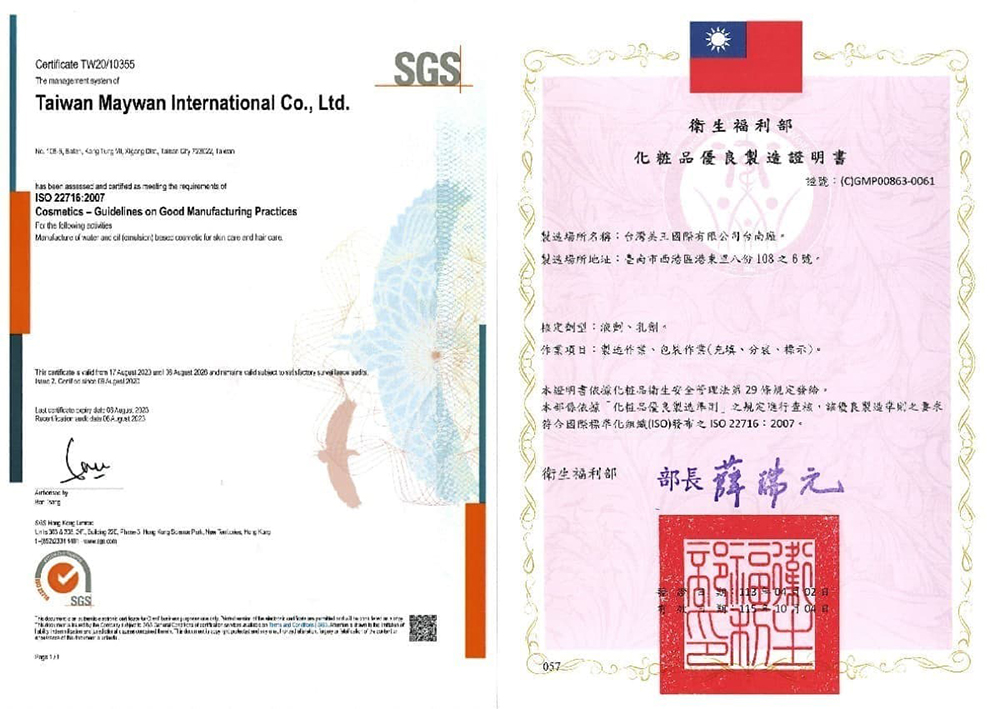

Taiwan Meiwang is a professional contract manufacturer holding both certifications. Whether you plan to focus on Taiwan’s domestic market or expand into overseas sales, you can proceed with mass production confidently and ensure stable, controllable quality.

[Further Reading] Understand Skincare Product Quality Testing from R&D to Market in 3 Minutes

3. Why Choosing a Certified Manufacturer Greatly Enhances Brand Competitiveness

Selecting an OEM/ODM manufacturer certified under ISO 22716 and Cosmetic GMP is not only about meeting quality standards—it ensures smoother, safer, and more competitive brand development from product launch to global expansion. Key benefits include:

- Smoother exports | Compliance with international standards improves cross-border sales efficiency: Factories with ISO documentation, batch records, and raw material traceability make it easier for products to pass import inspections in the EU and Southeast Asia.

- Peace of mind at launch | Regulatory compliance reduces risks of delisting or supply interruption: From July 1, 2026, cosmetic manufacturing in Taiwan will fully fall under mandatory GMP. Non-compliant factories will no longer be legally allowed to produce cosmetics.

| 1 | Full Regulatory Compliance | Cosmetic GMP is the basic manufacturing requirement in major markets (EU, U.S., Taiwan), ensuring controlled production, packaging, and storage. |

|---|---|---|

| 2 | Product Quality and Safety Assurance | Standardized SOPs, environmental monitoring, and batch management ensure consistent quality and reduce contamination risks. |

| 3 | Enhanced Trust and Global Competitiveness | GMP certification is a key indicator of credibility for distributors and international channels. |

| 4 | Optimized Management and Production Efficiency | Standardized processes and traceability systems reduce waste, improve quality, shorten lead times, and strengthen cost control. |

- Building consumer trust | High standards equal higher brand value: Certified factories provide transparent processes, reliable quality, and strong support for safety- and science-focused brand storytelling.

4. Mandatory Timeline for Cosmetic GMP in Taiwan

To align with international standards, Taiwan has established a clear timeline for mandatory GMP implementation:

- From July 1, 2024: Manufacturing sites for “specific-use cosmetics” (formerly medicated cosmetics, such as sunscreens and hair dyes) must fully comply with GMP.

- From July 1, 2025: General cosmetics for babies, lips, eyes, non-medicated toothpaste, and mouthwash must comply with GMP.

- From July 1, 2026: All general cosmetics (except exempt handmade soap) must comply with GMP.

This means GMP compliance is no longer optional—it is essential for survival. Early preparation helps avoid regulatory disruptions.

5. Taiwan Meiwang: Dual Certification for Your Strongest Quality Support

Taiwan Meiwang understands that quality is the foundation of every brand. We proactively obtained both ISO 22716 and Taiwan Cosmetic GMP certifications ahead of mandatory enforcement.

With over 20 years of OEM/ODM experience, we help brands navigate complex regulations, build complete PIF documentation, and successfully launch competitive products.

Interested in developing your own skincare products?

Contact us today to start building your next best-selling product.

6. FAQ – Frequently Asked Questions

1. How does working with a GMP/ISO 22716–certified factory help with PIF preparation?

Choosing a contract manufacturer with both ISO 22716 and GMP certifications significantly improves the efficiency and completeness of PIF preparation. Because all processes, records, and quality documents are established and managed in accordance with cosmetic GMP standards, required PIF materials—such as raw material data, microbiological reports, stability tests, and manufacturing records—are well documented. This reduces the need for supplemental submissions, shortens timelines, and streamlines the cosmetic safety assessment process.

[Further Reading] What Is the Required PIF for Cosmetics? Are You Ready?

2. What are the manufacturing differences between certified and non-certified factories?

The main differences include batch consistency, raw material lot management, equipment cleaning validation, environmental microbial monitoring, personnel hygiene training, and completeness of documentation. These differences are not visible on the outer packaging, but they directly affect product success rates, quality, and risk control. Starting July 1, 2026, GMP compliance will be mandatory in Taiwan; non-compliant factories will no longer be legally allowed to manufacture cosmetic products.

[Further Reading] How Much Does Compliance Matter for OEM/ODM Manufacturers? Two Key Principles You Must Know

3. When choosing a skincare OEM/ODM factory, is it necessary to have both ISO 22716 and Cosmetic GMP?

It is not strictly mandatory for a factory to hold both ISO 22716 and Cosmetic GMP certifications; however, since each serves different market needs, dual certification is highly recommended in practice.

ISO 22716 (international standard): Often a required import document for exports to the EU, Southeast Asia, the U.S., Japan, and Korea.

Taiwan Cosmetic GMP (TFDA-verified): Directly linked to Taiwan regulations and will be progressively mandatory starting in 2026. Non-compliant factories will not be allowed to manufacture products in Taiwan.

Therefore:

Taiwan domestic market only → GMP is essential

Export markets only → ISO 22716 is strongly recommended

Taiwan + overseas markets → A dual-certified factory is necessary to avoid regulatory roadblocks

Interested in developing your own exclusive skincare products?

Book a consultation and let us help you create your next best-selling skincare product.

- 3 essential key points for OEM/ODM skincare products! OEM skincare factory products and experience are crucial

- Anti-hair Loss Product Formula Analysis: Three Popular Non-medicinal Hair Care Ingredients Recommended

- 【A Must-Save Guide for Startups】Skincare OEM Factory Collaboration Guide|Prepare These 5 Things for Smoother Product Development!

- [2026 Cosmetic PIF Implementation Guide] Understand Regulations, Costs, and Penalties at a Glance | Professional OEM Assistance

- Grasping the new trend of exosomes: Applications and business opportunities of plant vesicles in skincare OEM/ODM

- How Are Skincare OEM Costs Calculated? Understanding MOQ Pricing and Small-Batch Manufacturing

- Learn about the quality inspection of skincare products from R&D, production to market launch in just three minutes!

- 2025 Hong Kong Beauty Expo (Cosmoprof Asia) | Post-Expo Highlights Summary