- Home

- OEM Process

Natural Shampoo, Conditioner,

Hair Styling Products, Body Wash OEM Process

-

Confirm demand and product positioning

Initially, we'll engage in in-depth discussions with the brand to clarify their needs, desired product types, functions, and market positioning, ensuring the R&D direction aligns with the target audience. Through demand interviews, we help brands identify their product's differentiated value and chart a development path aligned with market trends and brand philosophy.

-

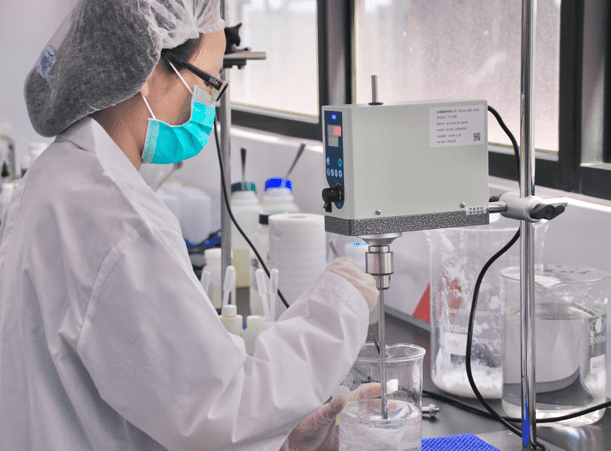

Prototype

Based on the product direction established after discussion, the R&D team will select appropriate formulas and raw materials, conduct small-scale trial production, and provide samples of different textures, fragrances, and packaging materials upon request. This phase allows brands to experience the differences in product effectiveness, scent, appearance, and skin feel, serving as a crucial basis for determining whether the product aligns with its positioning. It also helps identify potential issues, laying the foundation for subsequent adjustments and optimization.

-

Sample confirmation

Once the initial samples are complete, they are provided to the brand for trial use and feedback is collected. Necessary adjustments are then made to details such as texture, absorbency, efficacy, or fragrance. This phase focuses on ensuring that the product meets brand expectations in terms of user experience and performance, and is highly consistent with market positioning and brand philosophy before officially moving on to the next stage.

-

Quote

Once samples are confirmed, the factory will provide a complete quote based on factors such as the final formula, packaging material selection, production quantity, and inspection requirements. This quote includes unit price, delivery time, and related services. This transparent and traceable quote helps brands understand their cost structure and evaluate market pricing strategies.

-

Packaging confirmation

Once the formula is finalized, the packaging specifications required for the product, such as bottle material, capacity, and appearance, are confirmed simultaneously. This phase primarily ensures the packaging matches the product's characteristics. Brand owners are then given the opportunity to design the product themselves or outsource the design based on their needs. The factory will then confirm the packaging's feasibility and conduct sample testing to ensure smooth entry into production.

-

Production Scheduling and Manufacturing

Based on the final confirmed product specifications and order quantity, the factory will develop a comprehensive production schedule to ensure the smooth flow of all processes. The manufacturing process strictly adheres to international standards such as GMP and ISO 22716. Mixing, filling, and packaging operations are carried out in a dust-free environment, and standardized operating procedures ensure consistency. Dedicated personnel monitor and record every step of the process to ensure consistent product quality and safety, allowing brands to confidently deliver to the market.

-

Quality Assurance Inspection

After packaging, all finished products undergo multiple quality assurance inspections in accordance with regulatory requirements. In addition to visual inspections, functional testing, and quality verification, we also conduct microbiological testing, stability testing, and related safety assessments as needed to ensure that no quality risks arise during storage and use.

-

Ship

After all products have been inspected and confirmed as qualified, they undergo packaging, label verification, and final approval according to a pre-determined schedule to ensure that every batch of goods meets specifications. The factory will provide a complete inspection report or Certificate of Authenticity (COA) with each shipment, providing brands with reliable documentation for market distribution and import/export inspections, enabling them to quickly and legally launch their products into the market.

-

Product support services

After product shipment, the factory provides essential follow-up support to help brands maintain smooth market operations. Whether it's additional orders, planning production batches, or updating compliance documents to address regulatory changes, we can assist. This comprehensive after-sales support helps brands maintain product stability and market continuity amidst fierce competition.

Why Choose Taiwan Maywan?

Professional R&D team

- ◆R&D

- ◆Machinery

- ◆Custom Formula

Complete machinery and equipment

- ◆High-Spec Plant

- ◆Diverse Products

Strict quality control

- ◆Quality Checked

- ◆GMP

- ◆ISO 22716

Multiple tests ensure quality

- ◆Microbe Check

- ◆Stability Test

- ◆COA Report

PIF & Full assistance in product registration

- ◆Regulatory Consulting

- ◆Product Filing

Education and training

- ◆Refined Tech

- ◆Driving Innovation

- ◆Service Variety